Industrial Safety

Are we learning from safety incidents?

Risks are always present and there is a need to understand and manage risks proactively.

WITHIN THE FIRST three weeks of January 2021, there were three major incidents: a toxic gas leak that resulted in at least four fatalities in Rourkela Steel Plant, a fire that consumed 10 babies in a hospital in Bhandara and another fire that resulted in loss of at least five lives in Serum Institute, Pune. These on the back of a few major incidents that occurred in 2020 that include gas leaks in Baghjan Oil India and Vizag LG Polymers and explosions in Yashahvi Rasaya, Dahej and Neyveli Lignite Corporation.

Why is there a sudden increase in the number of such accidents?

Risk Accelerators

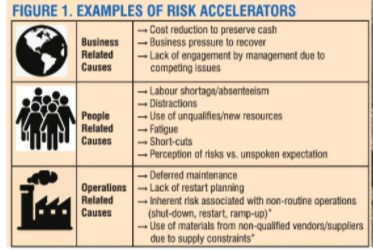

The emergence of the Covid-19 pandemic has prompted most, if not all, companies to refocus their priorities to ensuring that workplace infection is prevented. The decisions made in response to Covid-19 and the attention demanded by the pandemic have resulted in neglect and acceleration of other risks that have always been present, particularly safety risks. These risk accelerators have had serious consequences to the companies’ bottom line, and the safety of employees and surrounding communities. DuPont Sustainable Solutions (DSS) compiled the most commonly cited risk accelerators based on what we have heard from various companies globally (see Figure 1).

Learn from the past…

Recent spate of industrial incidents have called for a serious introspection regarding the consciousness around industrial safety in India. Interestingly, it was reported that in the

, required environmental clearances had not been obtained. While enforcement efforts are more often reactive and fragmented, the responsibility for compliance lies with the companies and not just the regulatory agency. The primary purpose of these clearances are to ensure that all possible risks are identified and controls put in place to mitigate the risk. Neglecting this important step means risks are neither anticipated nor are controls put in place. Simply identifying major non-compliances after the occurrence of an incident serves no meaningful purpose.

A common theme arising from the incident investigation reports is that required internal safety procedures were not adhered to. It is not just about workers following the procedures alone. It has to do with decisions made across the entire supply chain. For example, use of an improper gasket procured from the local market has been identified as a probable cause of leak which led to the massive fire at ONGC’s Hazira gas plant in the early hours of 24 September, 2020.

Some of the underlying conditions that inhibit safety improvement include an abundance of cheap labour, paltry spending on Occupational Safety & Health (OSH), stakeholder resignation to unsafe OSH conditions, inadequate implementation of existing legislation, lack of reliable OSH data and measurement and a shortage of OSH expertise and professional institutions.

Implementing the lessons learned

Make in India and Atmanirbhar Bharat will undoubtedly be major drivers for change with both positive and negative impacts on levels of compliance and good practice at the workplace. There is a huge opportunity to capture lessons learnt from other countries and prevent the recurrence of such incidents in India.

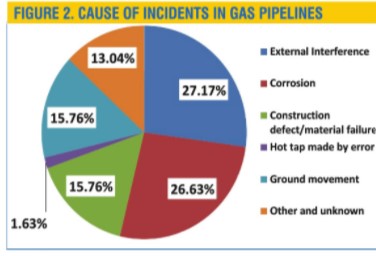

In the January edition, the cover story of Industrial Economist was focused on “Cheers on the Gas Front. There is a great opportunity in adopting international best practices that not only improves safety but also improves productivity. A huge amount of data and insights are available in the public domain about incidents in the gas pipeline. One such source is shown in Figure 2 that is based on incidents over a 10 year period compiled by European Gas pipeline Incident data (EGIG). The Hazardous Material Safety Administration under the Department of Transportation has almost 50 years of data on pipeline incidents. As companies are embarking on ambitious plans in terms of laying pipelines and expanding gas distribution networks, it is imperative that companies proactively incorporate lessons from the abundant information and insights available in the public domain and prevent catastrophic incidents.

Industrial Safety Evolution in India

The Bhopal gas tragedy was possibly the single largest trigger for increased regulations worldwide, including India. However, there is a level of cohesion necessary among regulatory agencies, industry associations, companies and the public to achieve a progressive reduction of work-related fatalities, accidents, and diseases. The new legislation Occupational Safety, Health and Working Conditions Code, 2020 has consolidated 13 Acts that regulate health, safety and working conditions and is a step in the right direction.

Over the last 20 years, several leading companies, such as Tatas, Birlas, Reliance, Jindals, Hindustan Zinc… have adopted international best practices. The starting point for all of these companies was a realisation at the leadership level of the need to have a structured and robust approach to increase awareness and create a culture of safety. Industry associations such as CII, FICCI and the Indian Chemical Council (ICC) have all embarked on increasing the level of safety consciousness among their members. DSS has been working with companies across the spectrum to increase safety awareness and prevent injuries. While the awareness has increased, the journey has just begun. The data that is available in the public domain seems to be outdated.

Behavioural Reinforcement

A major challenge in measuring and improving India’s workforce Occupational Safety & Health is that data is available for only 10 per cent of the workforce employed in the organised formal sector, mainly in industry, mining and some services.

Each time a person takes an action to deviate from an established norm or rule and gets away with it, behavioural reinforcement takes place. As an example, if I jump a red traffic light and get away with it, then I get emboldened to do this again. And every time I do it and get away, then such deviations become a way of life, a habit. This normalisation of deviations is one of the critical factors that contribute to incidents and accidents in industrial sites. Risks are always present and there is a need to understand and manage risks proactively every single time.

A critical component that can significantly enhance the safety consciousness is the span of influence of people in power. It does start with the leadership. Tata Steel introduced measures to protect employees long before legislation to the effect was introduced. Tata Steel chose to adopt international best practices in safety to enhance the level of safety consciousness. CEOs B Muthuraman, H M Nerurkar and T V Narendran have all personally committed to achieve excellence in safety. They built upon efforts made by their predecessors and hence, safety is now respected as a core value in Tata Steel.

Technology and Industry Safety

The use of technology can significantly enhance the consciousness of the frontline workforce. Digital apps, including e-learning content, are available at affordable cost and at the click of a button using a mobile phone. This should particularly be a boon for small and medium enterprises to raise levels of awareness for the employees at an affordable cost and time.

Author is the Managing Director for DuPont Sustainable Solutions Asia Pacific, based in Singapore.